How CNC Refurbishing can save you factory from the capital crunch caused due to COVID?

Every factory has seen a slow down in flow of capital due to COVID.

In fact I have personally seen a lot of my customers slow down their capital investments due to COVID.

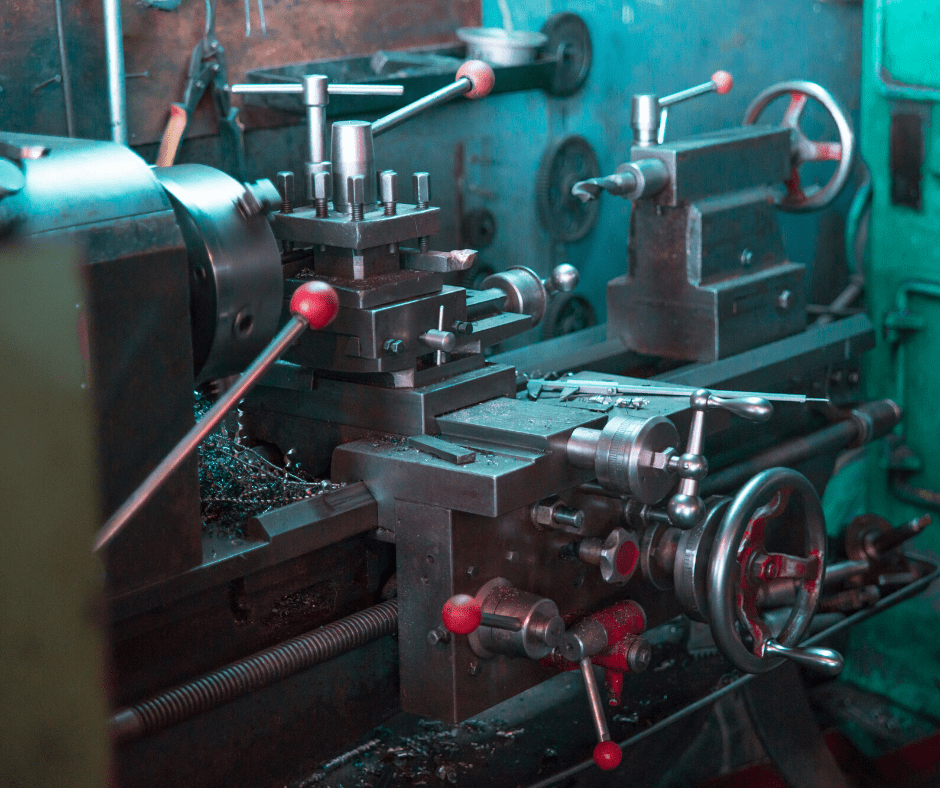

So, how does a factory manage old machines which are breaking down and need to be "replaced"?

CNC Refurbishing has always been an option.

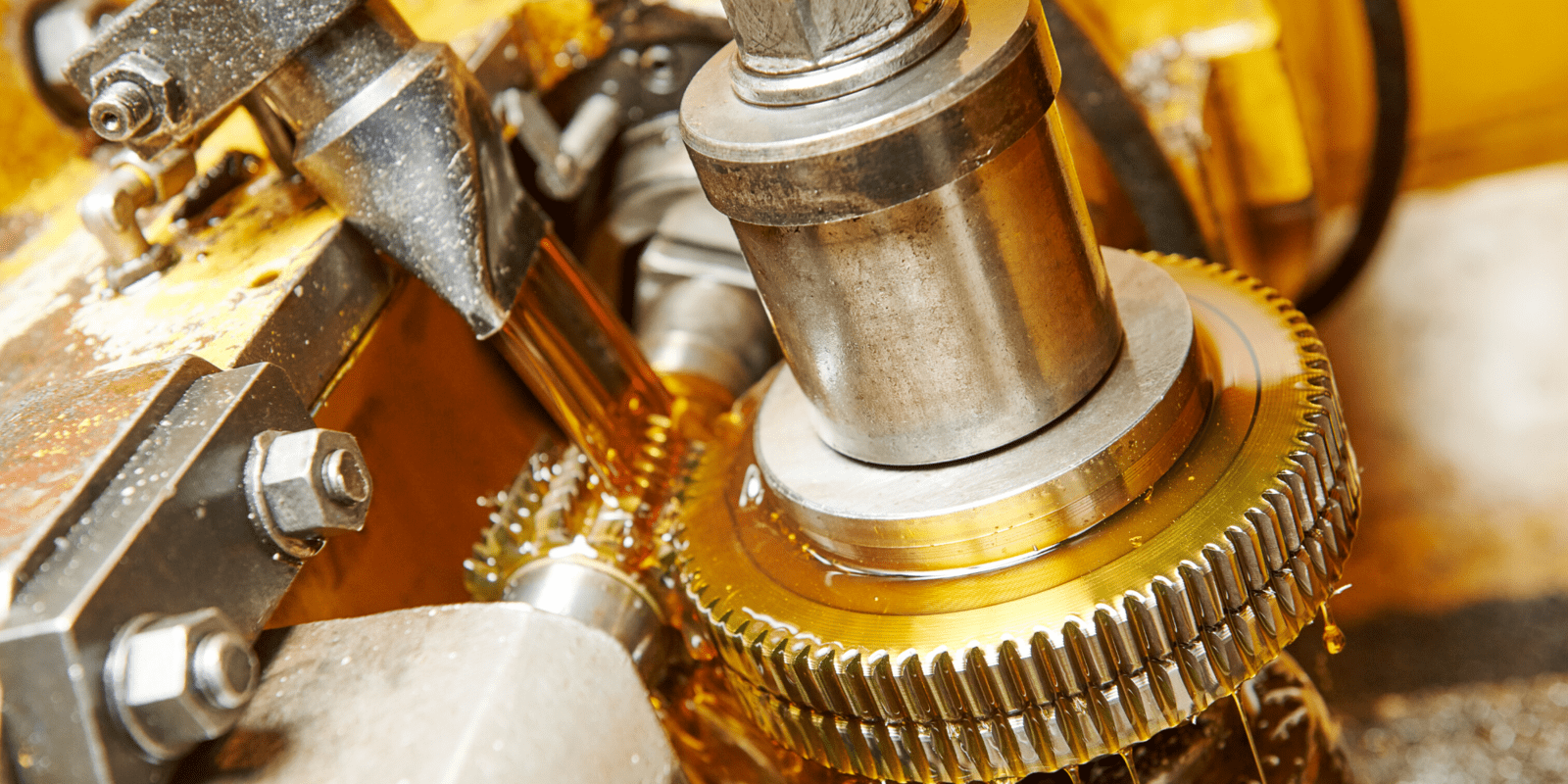

Here are some statistics to consider about CNC Refurbishing

- Costs 20-30% of the total cost of a new machine

- Can extend the life your machine almost 1.7 times it was initially planned to be replaced

- Gives you the ability to retain various jigs, fixtures this can be a huge saving especially for special part manufacturers - who have made huge investments in these custom jigs and fixtures - 100% cost saving

- Overall it takes half the time to go live with CNC Refurbishing instead of buying a new CNC Machine.

- Your factory saves almost 80% of the cost of training - as apart from few upgrades, your existing staff is already trained!

So I urge you to do this, consider Refurbishing to Extend life of your existing CNC Infrastructure.

If you're looking for quality CNC Machine Reconditioning/Remanufacturing/Retrofit, we have what it takes. Laven is dedicated in providing the best machine services globally. We are specialists when it comes to all types of machine reconditioning and inspection including grinding machines, lathes, milling machines, vertical machining centers, horizontal machining centres & more!

Comment below if you have any questions.