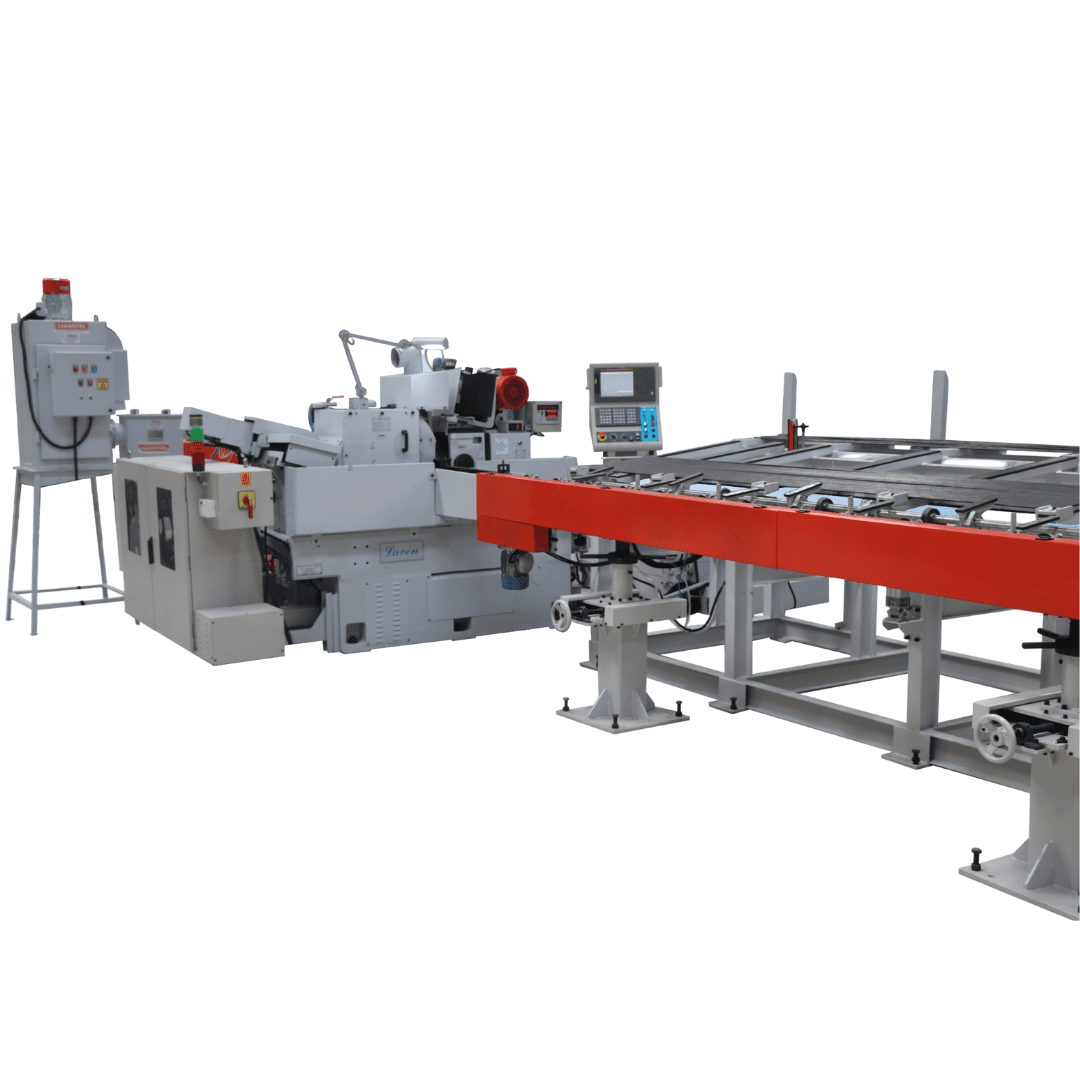

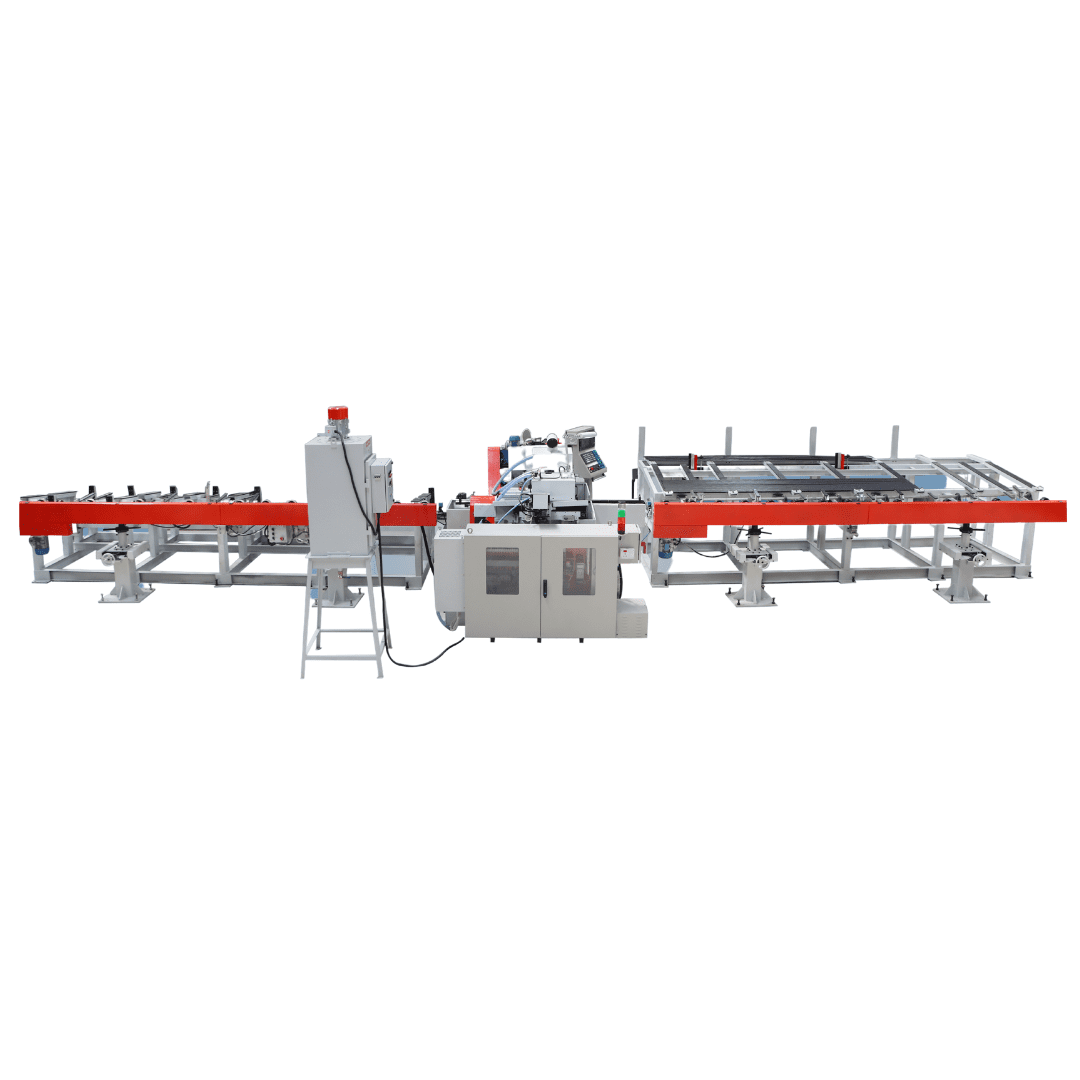

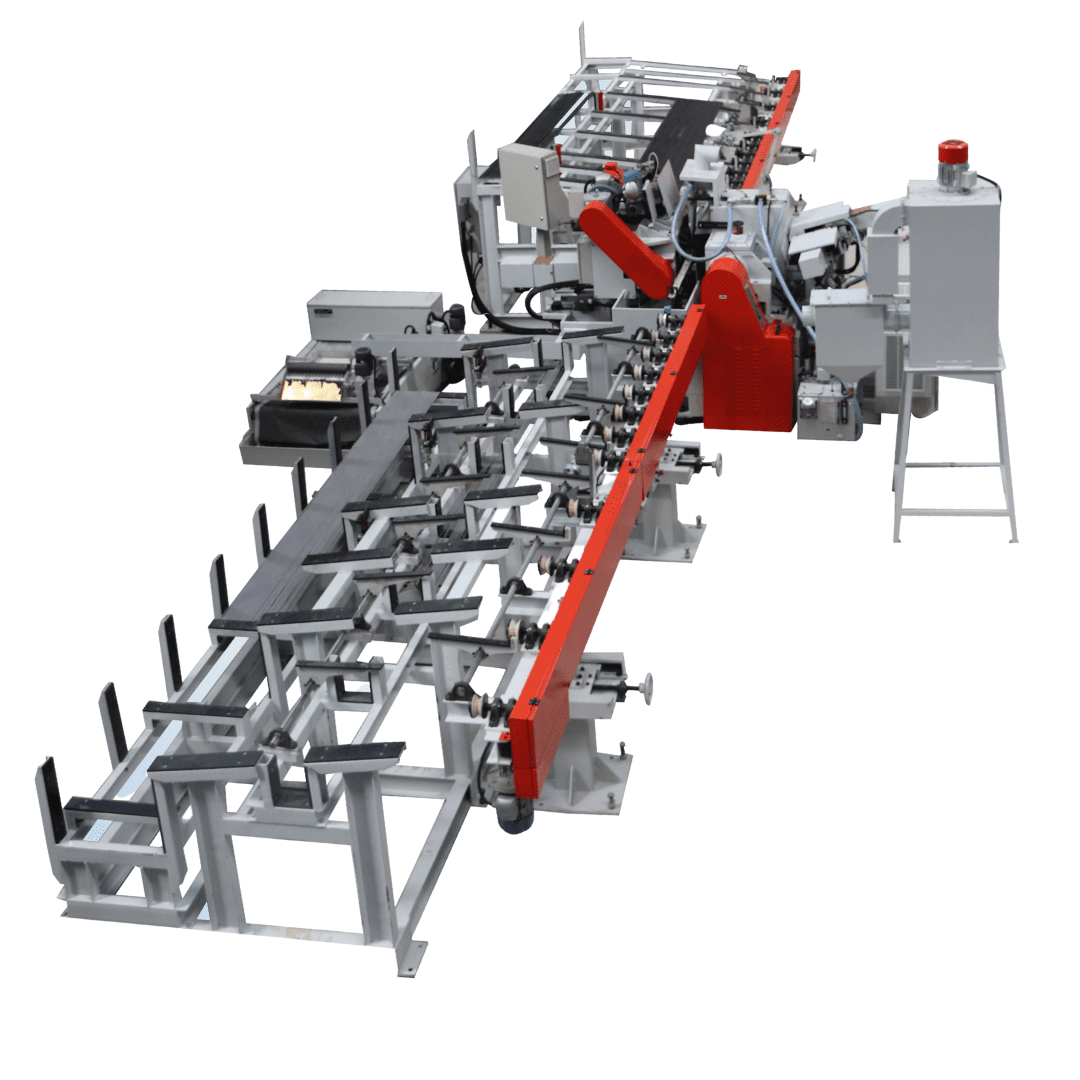

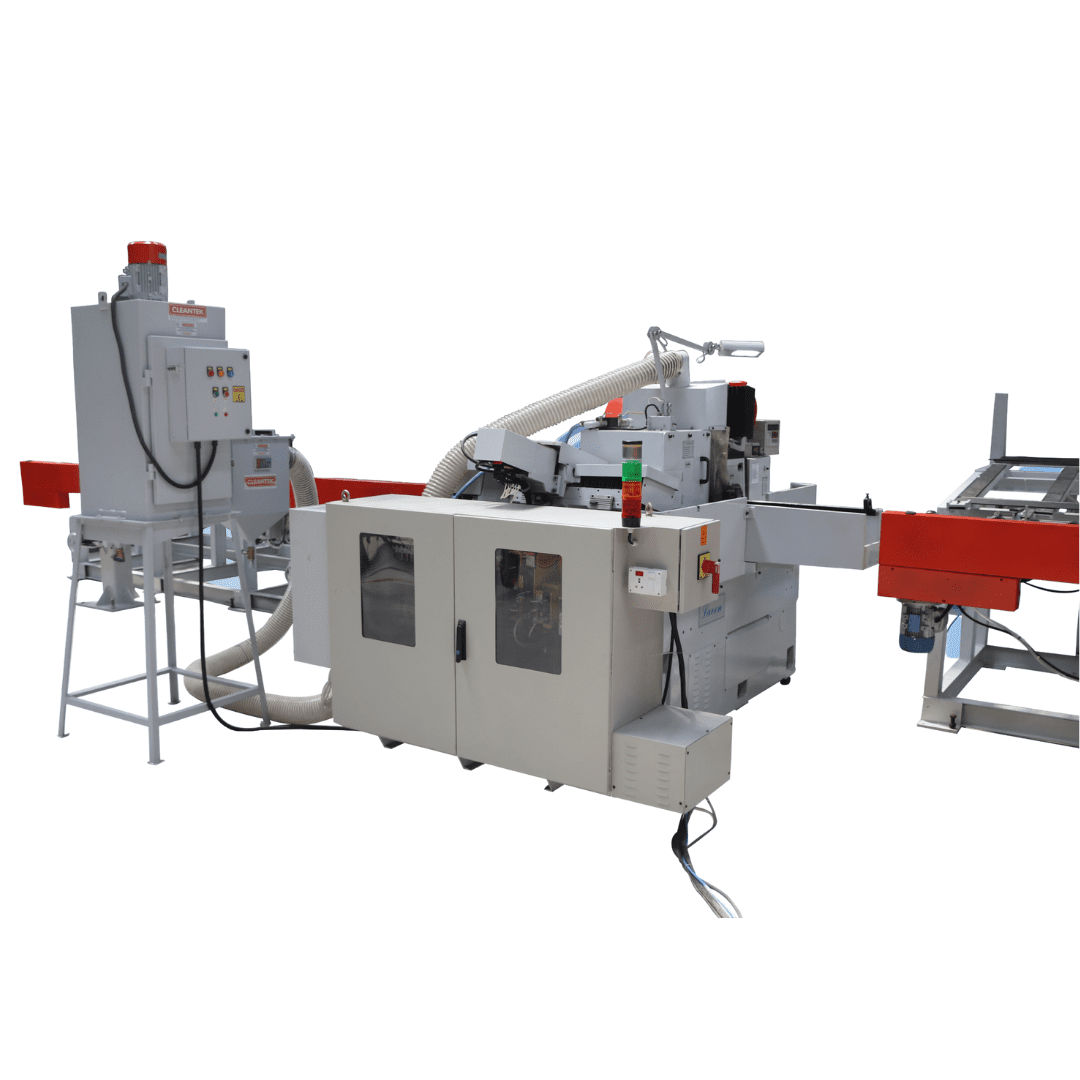

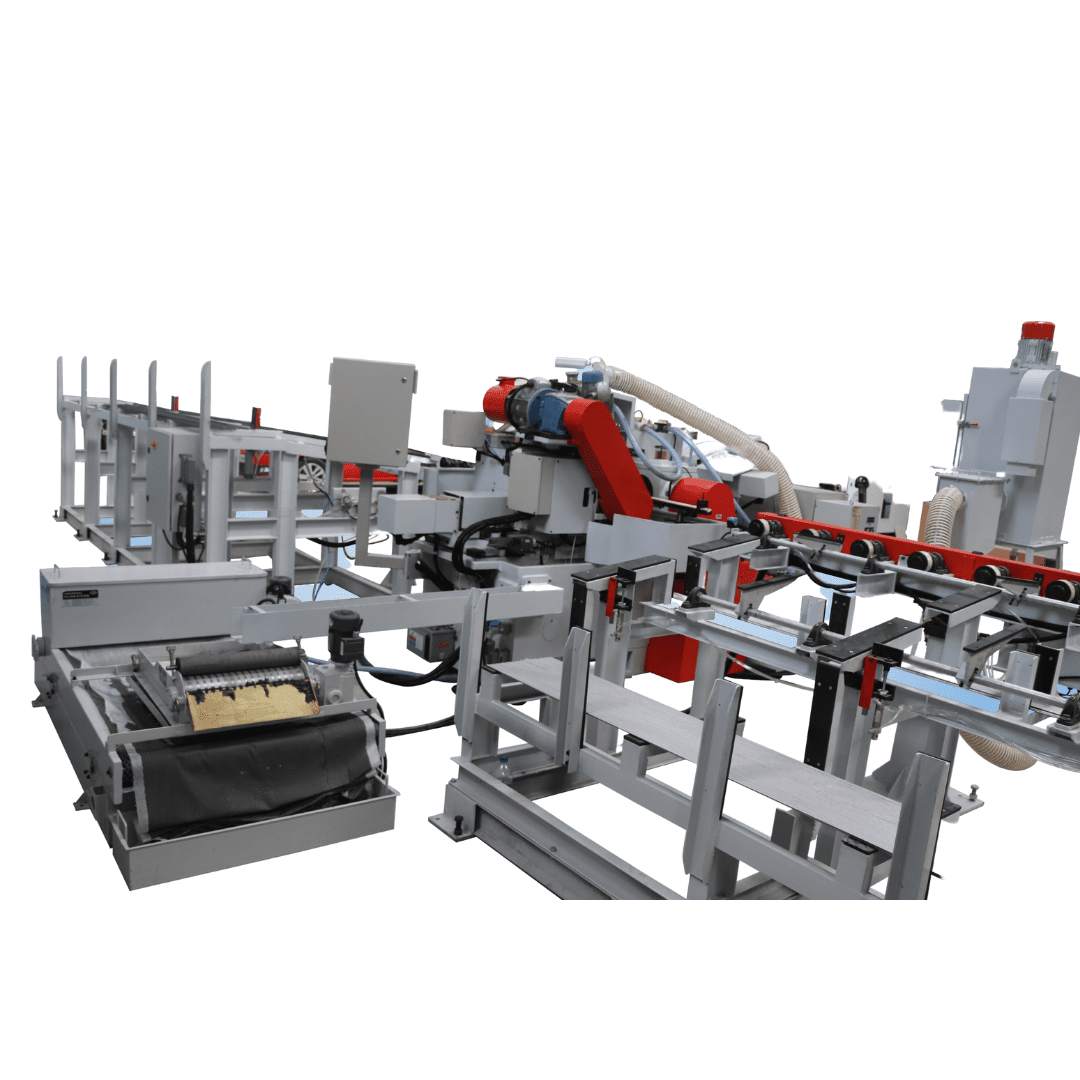

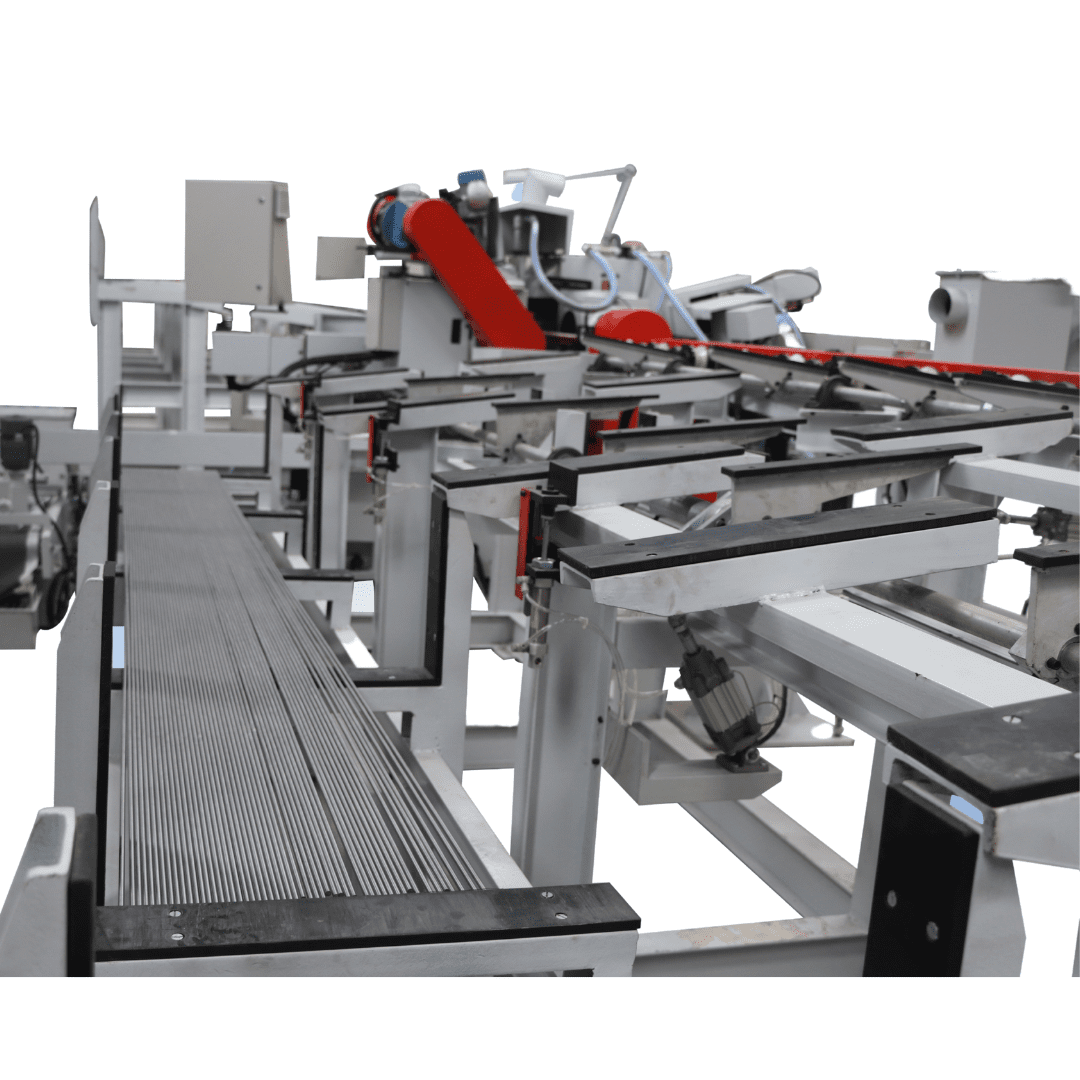

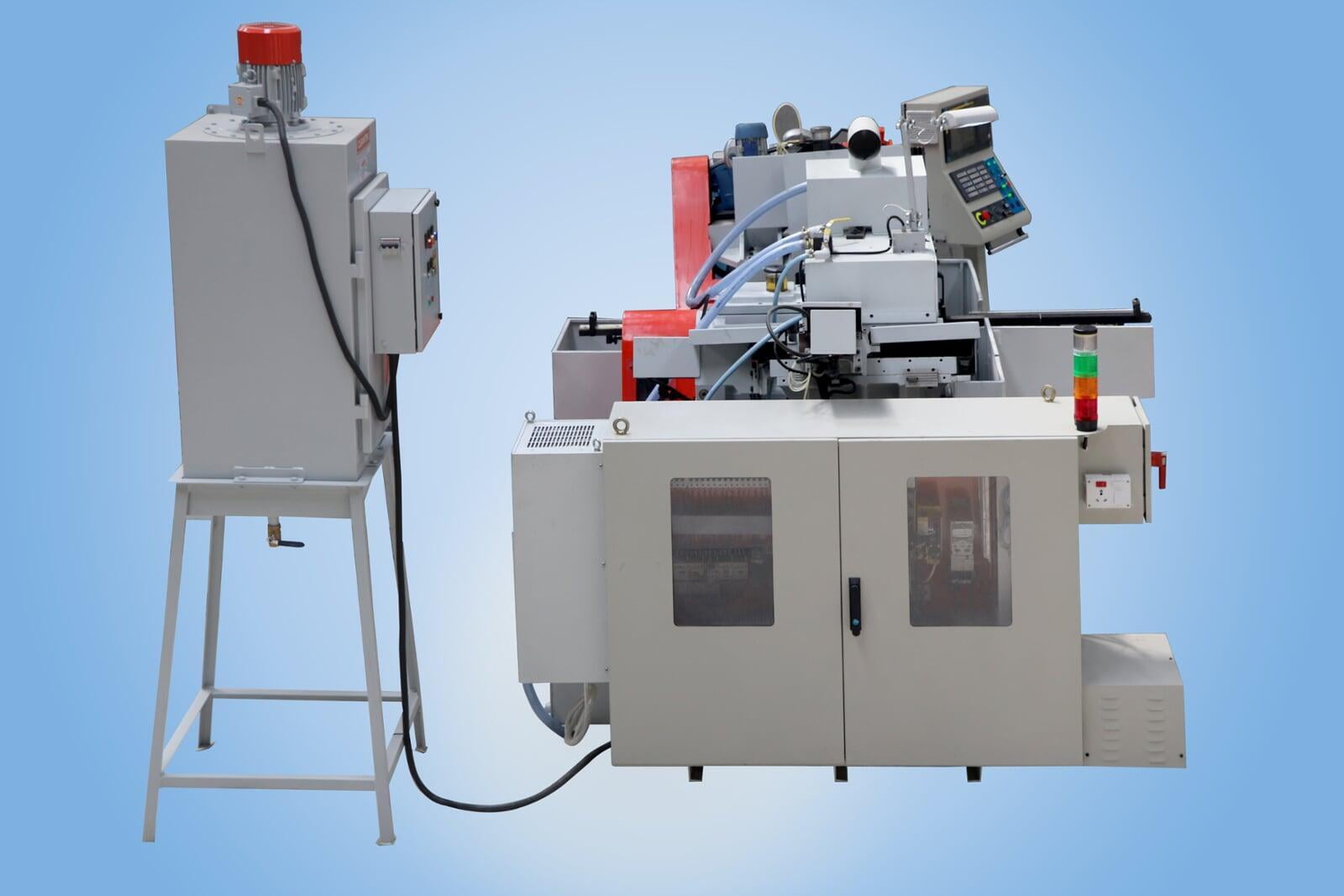

CG 600

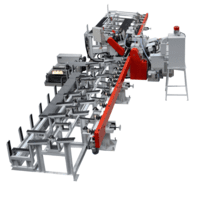

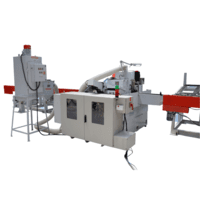

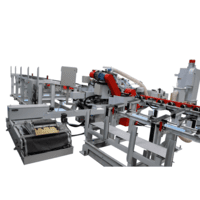

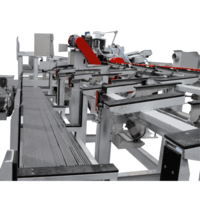

Discover the Laven CG 600, a pinnacle of bar grinding machinery, designed to deliver with precision and built to last. Ideal for a broad spectrum of cylindrical tasks.

Key Features

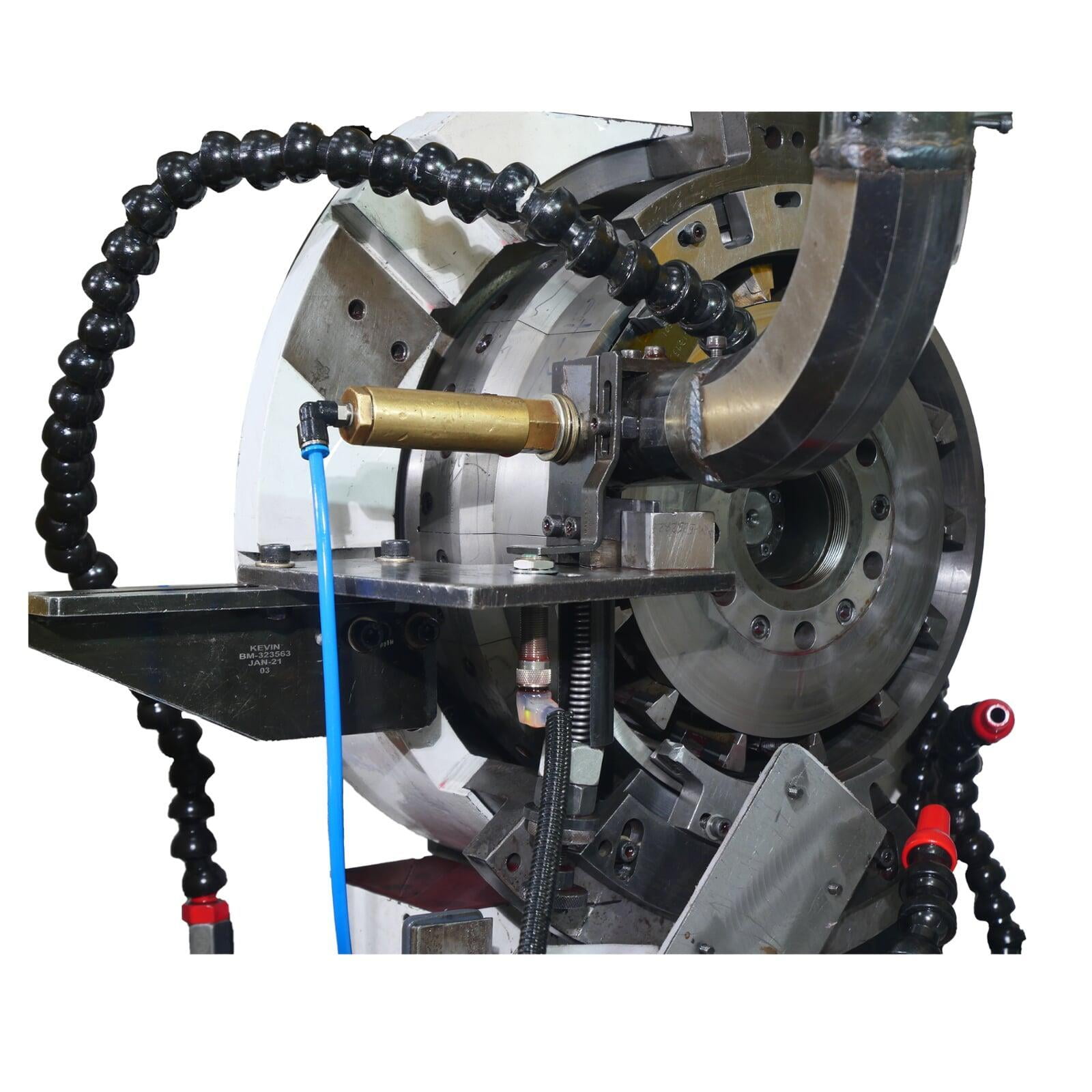

- High Precision: Designed for creating parts with the tightest tolerances and supreme accuracy, the CG 600 serves critical industries including aerospace and medical.

- Automation: Empowered by advanced CNC technology for streamlined and consistent grinding operations."

- Versatility: Capable of handling diverse materials and geometries, from engine valves to complex spindles and rollers.

Visualize the efficiency and precision of the CG 600 in full operation.

Specifications

CAPACITY

UNIT

SLV/CG/600

Min-Max Diameter

mm

Ø 3 – Ø 100

Length

mm

250

Center Height

mm

240

CAPACITY | UNIT | SLV/CG/600 |

Min-Max Diameter | mm | Ø 3 – Ø 100 |

Length | mm | 250 |

Center Height | mm | 240 |

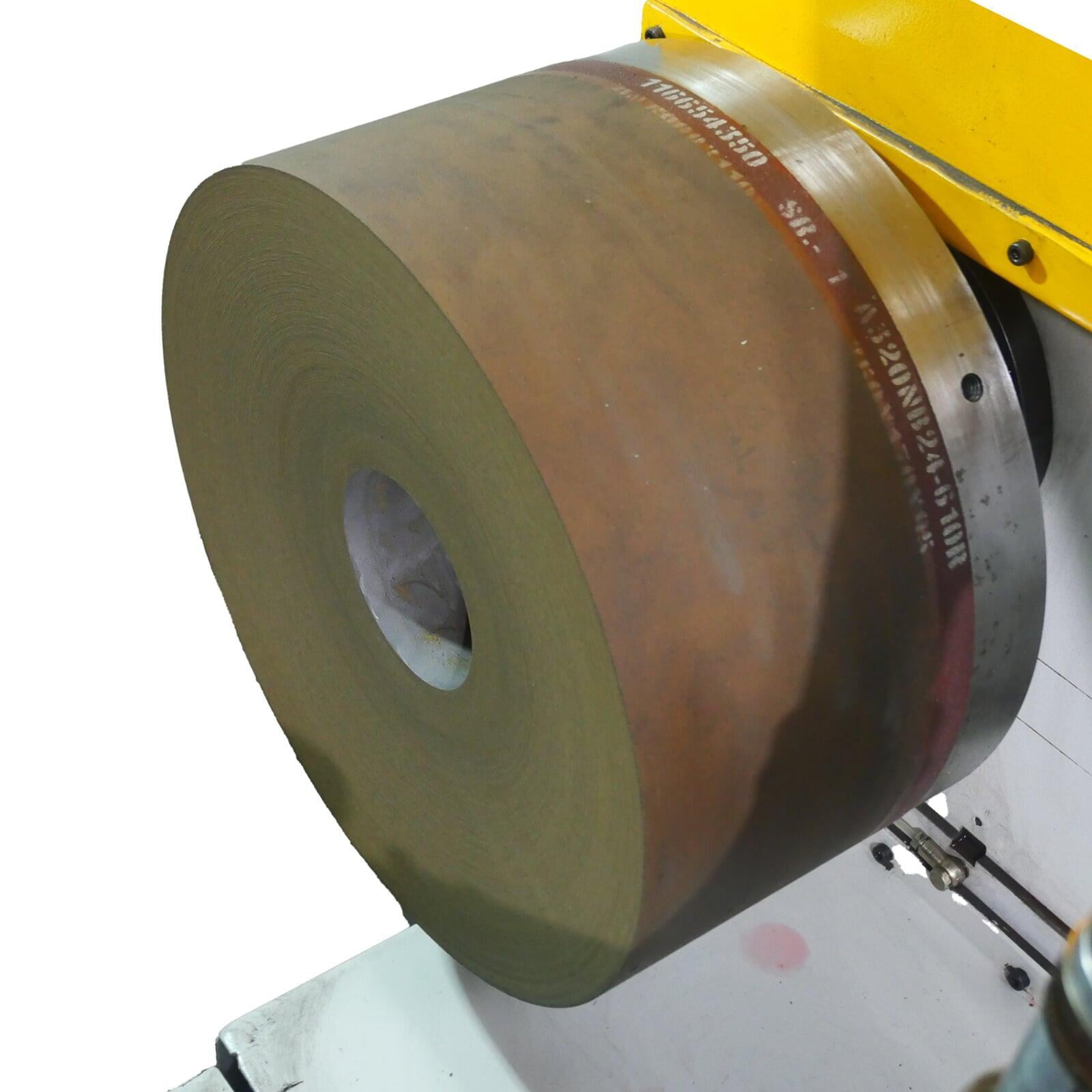

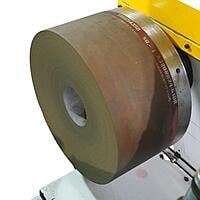

GRINDING WHEEL

OD x Width x ID

mm

Ø 610 x 250 x Ø 304.8

Minimum Diameter

mm

Ø 400

Wheel surface speed

m / sec

45

Motor Power

kw (HP)

22 (30)

Grinding wheel Speed

rpm

1410

GRINDING WHEEL |

|

|

OD x Width x ID | mm | Ø 610 x 250 x Ø 304.8 |

Minimum Diameter | mm | Ø 400 |

Wheel surface speed | m / sec | 45 |

Motor Power | kw (HP) | 22 (30) |

Grinding wheel Speed | rpm | 1410 |

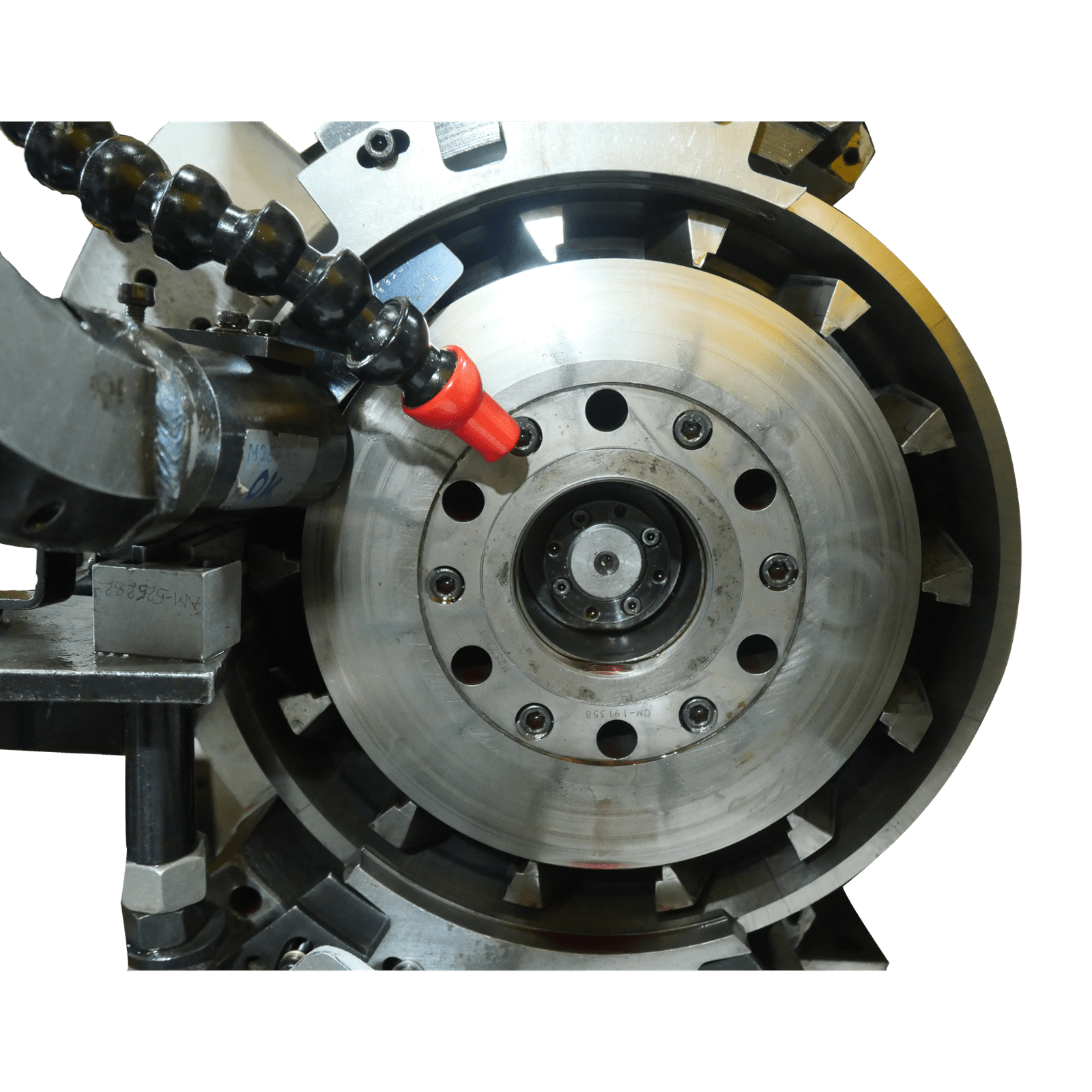

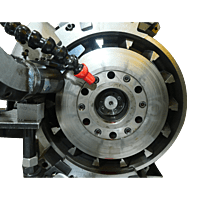

REGULATING WHEEL

OD x Width x ID

mm

Ø 300 x 250 x 127

Speed range

rpm

10 – 300

Regulating wheel tilting angle

degree

-3°~+5°

Motor power

kw / rpm

3.7 / 1450

REGULATING WHEEL |

|

|

OD x Width x ID | mm | Ø 300 x 250 x 127 |

Speed range | rpm | 10 – 300 |

Regulating wheel tilting angle | degree | -3°~+5° |

Motor power | kw / rpm | 3.7 / 1450 |

IN-FEED SLIDE

In-Feed stroke

mm

150

Least Count

mm

0.001

Swivel on in-feed slide

degree

±1°

Servo motor torque

Nm

12

IN-FEED SLIDE |

|

|

In-Feed stroke | mm | 150 |

Least Count | mm | 0.001 |

Swivel on in-feed slide | degree | ±1° |

Servo motor torque | Nm | 12 |

GRINDING WHEEL DRESSER – TRAVERSE

CNC

Slide stroke

mm

290

Least Count

mm

0.001

Servo motor torque

Nm

4

GRINDING WHEEL DRESSER – TRAVERSE |

| CNC |

Slide stroke | mm | 290 |

Least Count | mm | 0.001 |

Servo motor torque | Nm | 4 |

GRINDING WHEEL DRESSER – DEPTH

CNC

Slide stroke

mm

100

Least Count

mm

0.001

Servo motor torque

Nm

4

GRINDING WHEEL DRESSER – DEPTH |

| CNC |

Slide stroke | mm | 100 |

Least Count | mm | 0.001 |

Servo motor torque | Nm | 4 |

REGULATING WHEEL DRESSER – TRAVERSE

Ball screw with Gear Motor & VFD

(Optional CNC Dresser)Slide stroke

mm

290

Feed rate

mm / min

50 - 200

REGULATING WHEEL DRESSER – TRAVERSE |

| Ball screw with Gear Motor & VFD (Optional CNC Dresser) |

Slide stroke | mm | 290 |

Feed rate | mm / min | 50 - 200 |

REGULATING WHEEL DRESSER – DEPTH

Manual Control

(Optional CNC Dresser)

REGULATING WHEEL DRESSER – DEPTH |

| Manual Control (Optional CNC Dresser) |

CONTROL SYSTEM

Standard

FANUC

Optional

Siemens / Mitsubishi / Allen Bradley

CONTROL SYSTEM |

|

|

Standard |

| FANUC |

Optional |

| Siemens / Mitsubishi / Allen Bradley |

MACHINE SIZE

L x W x H

mm

3150 x 1900 x 1850

Weight

kg

Approx. 6000

MACHINE SIZE |

|

|

L x W x H | mm | 3150 x 1900 x 1850 |

Weight | kg | Approx. 6000 |