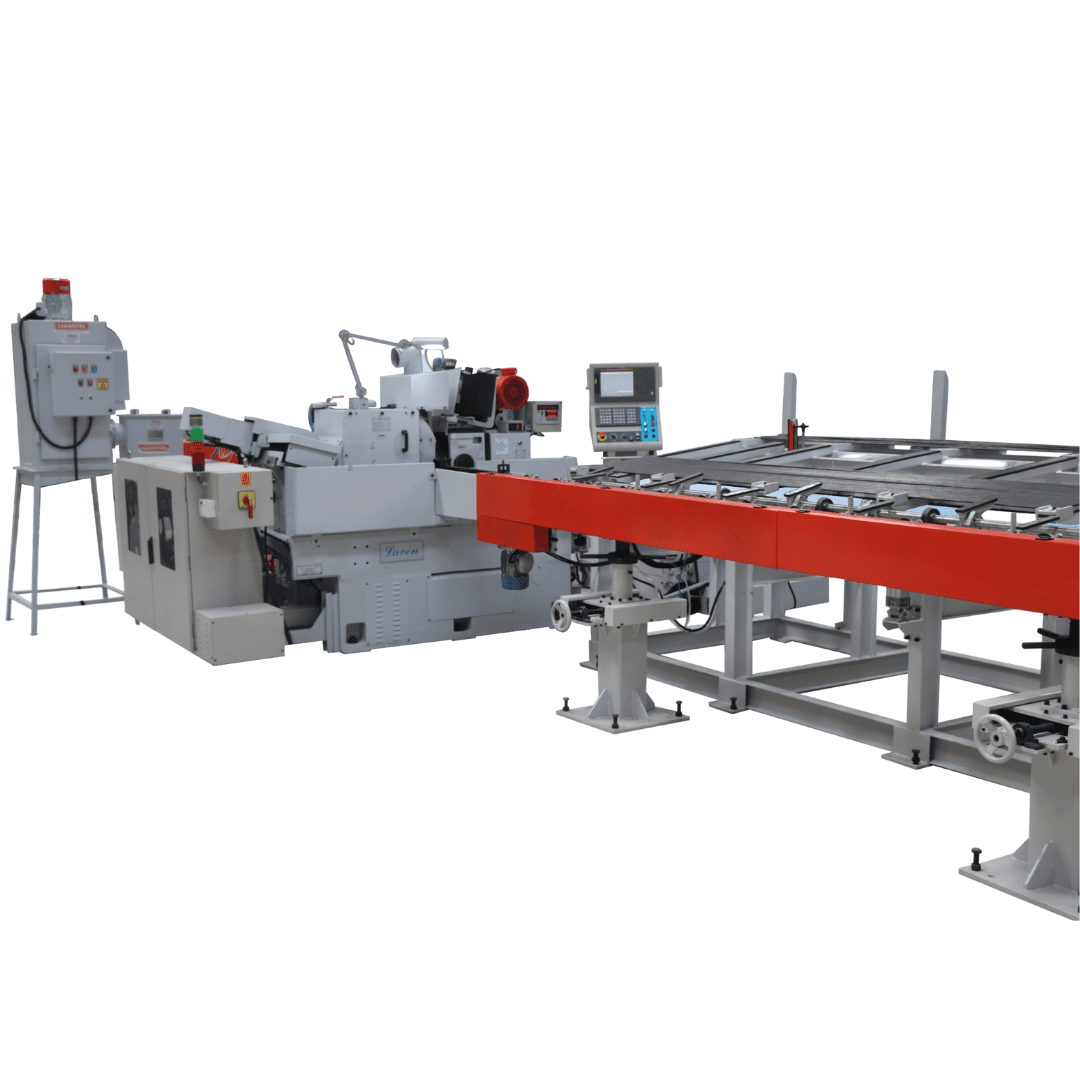

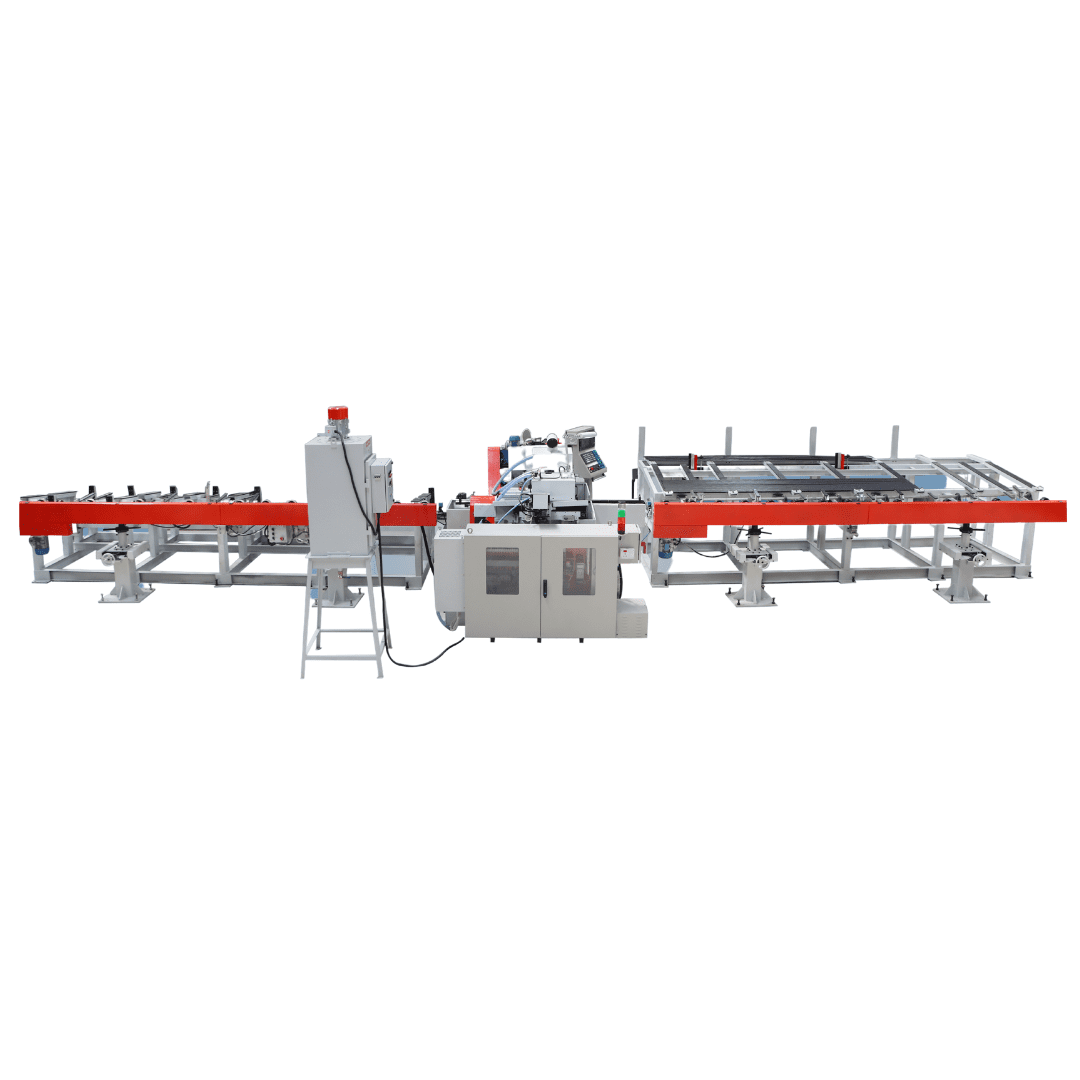

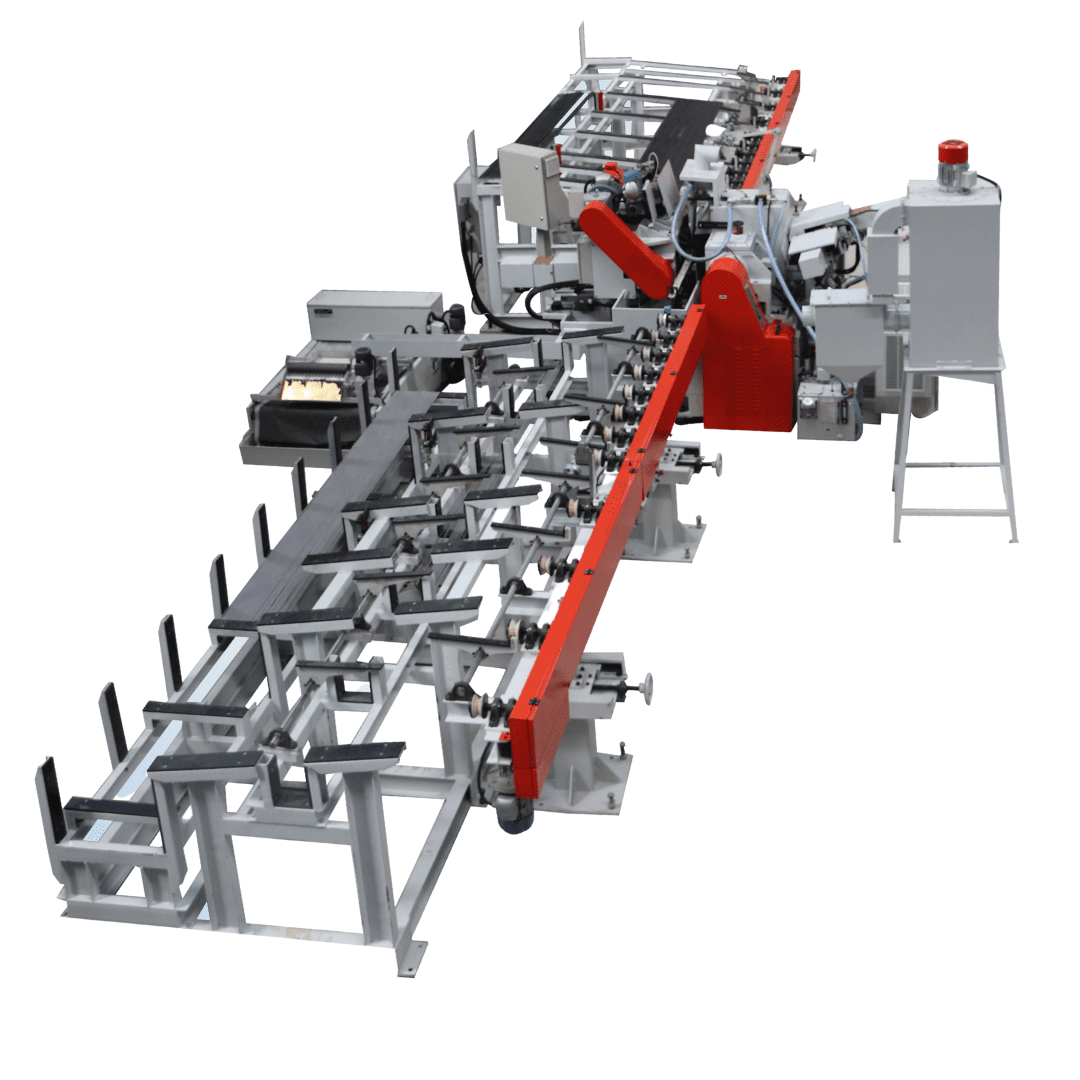

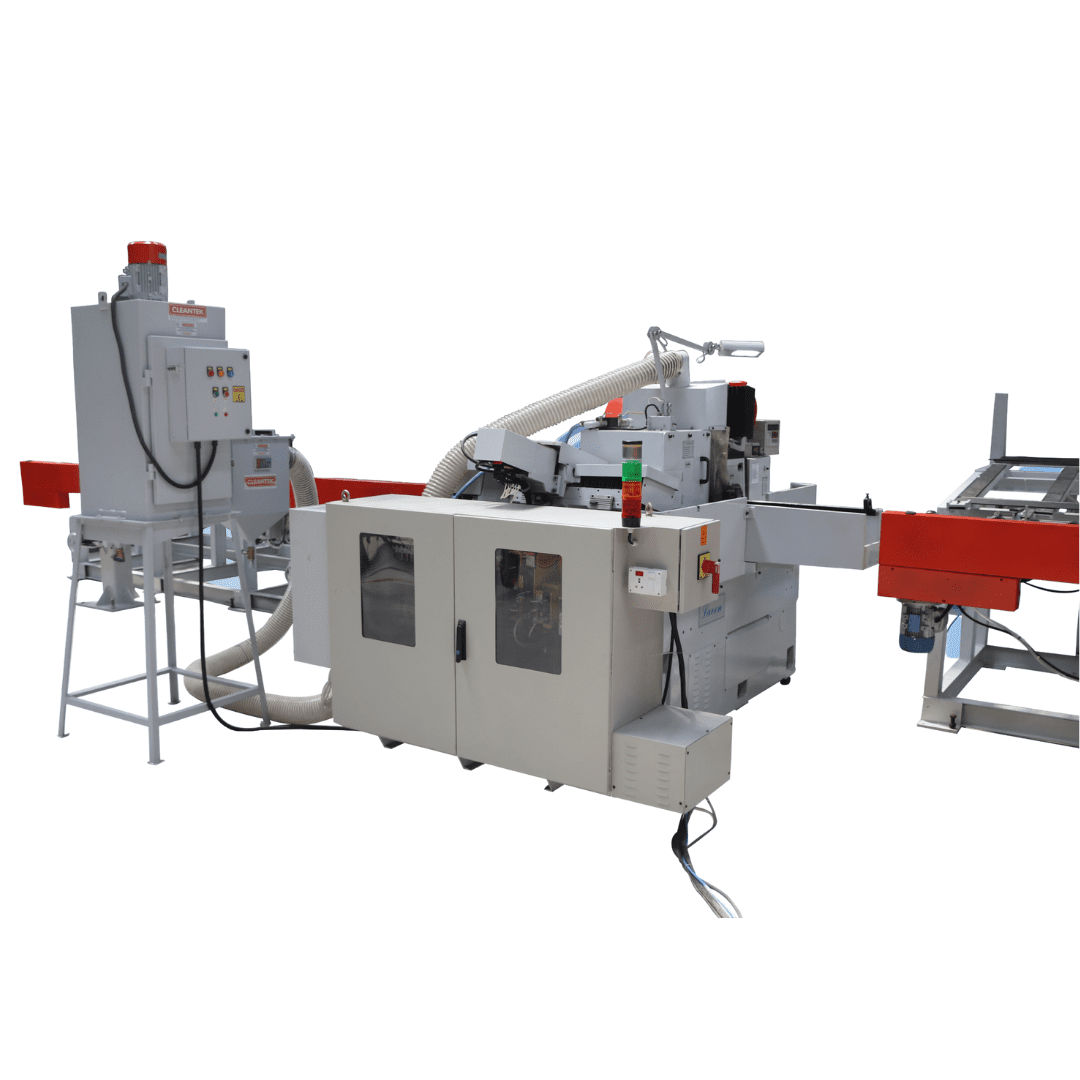

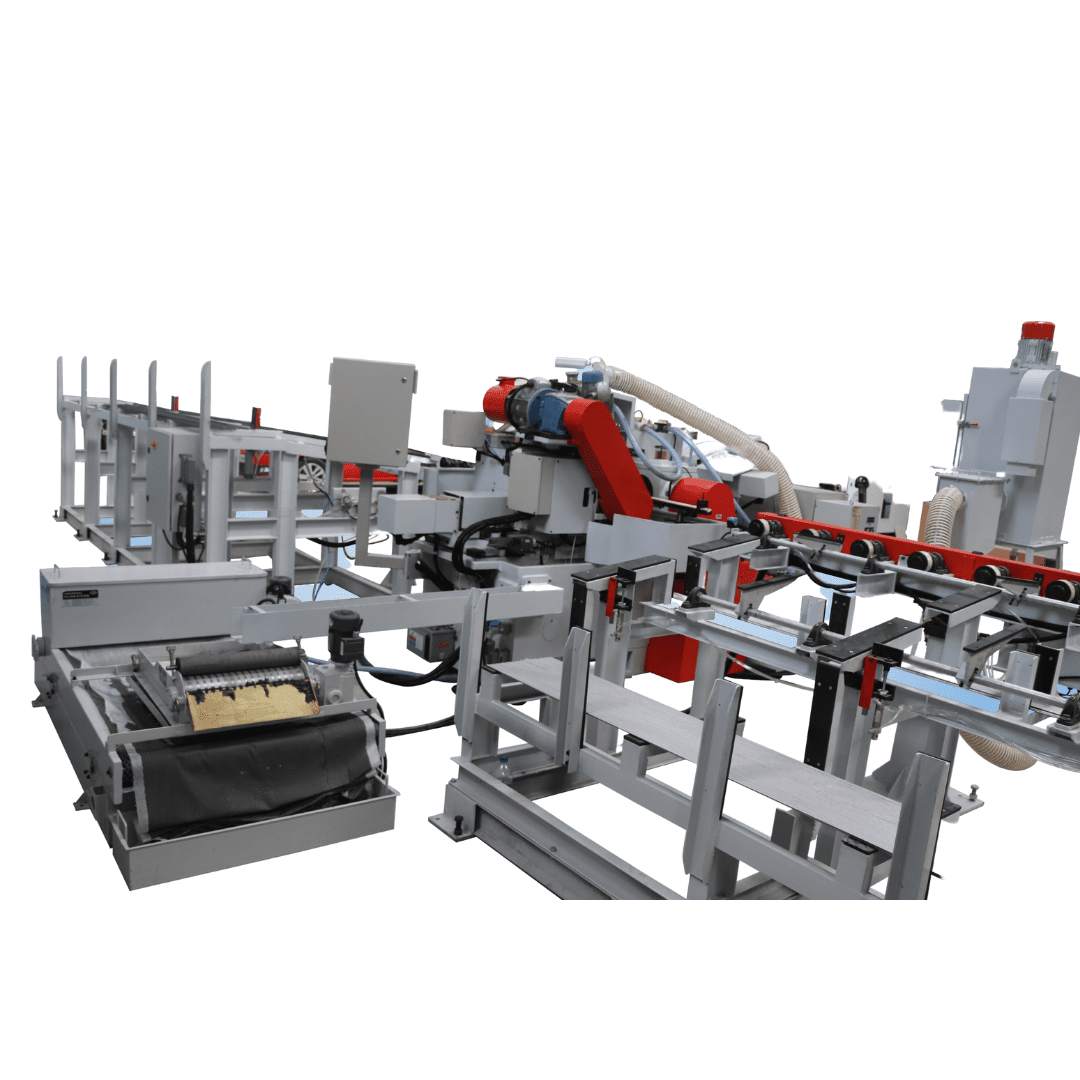

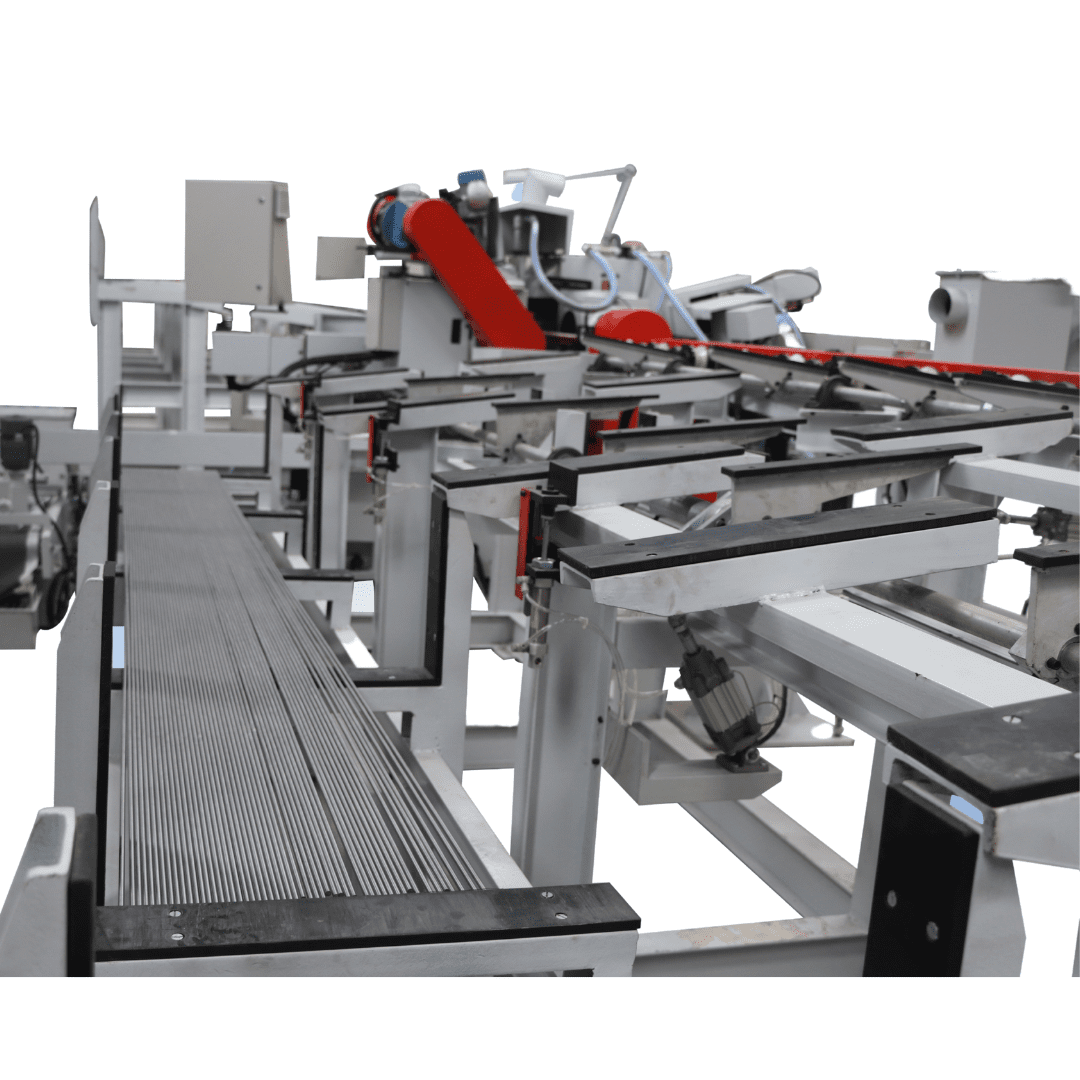

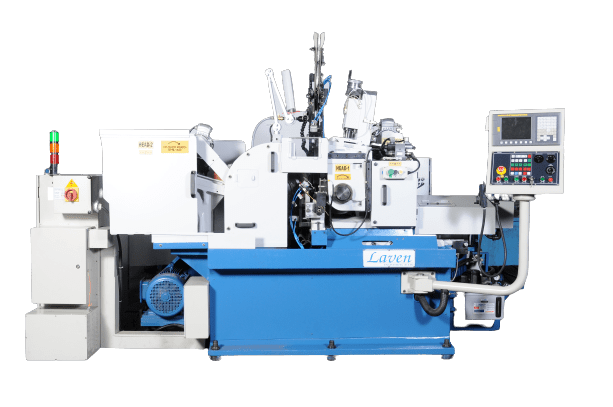

SLV/CG/400

Laven Manufactures world class CNC Centre-less grinding machines delivering excellent precision and high accuracy.

CNC Centerless Grinding Machine For In-Feed and Thru-feed Application

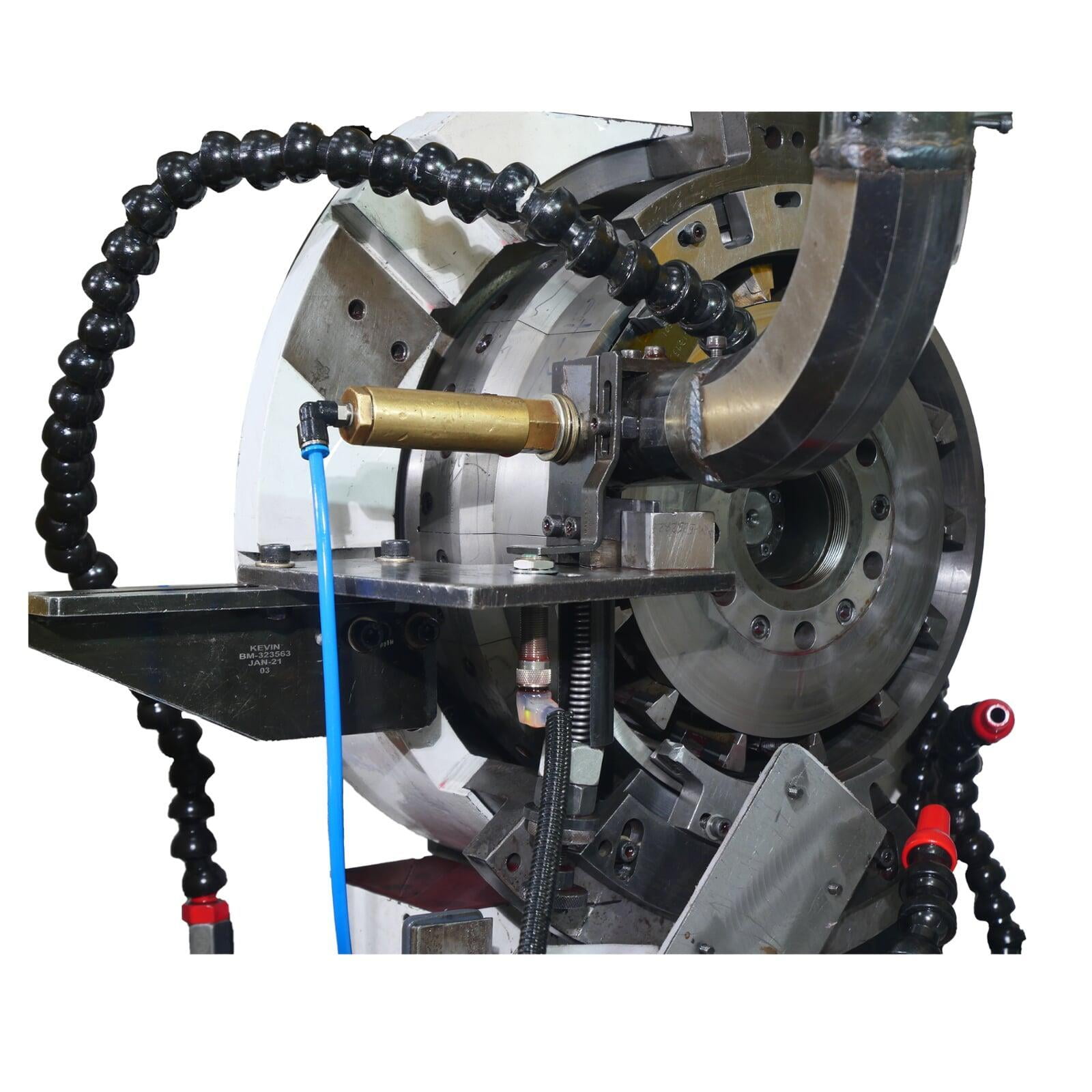

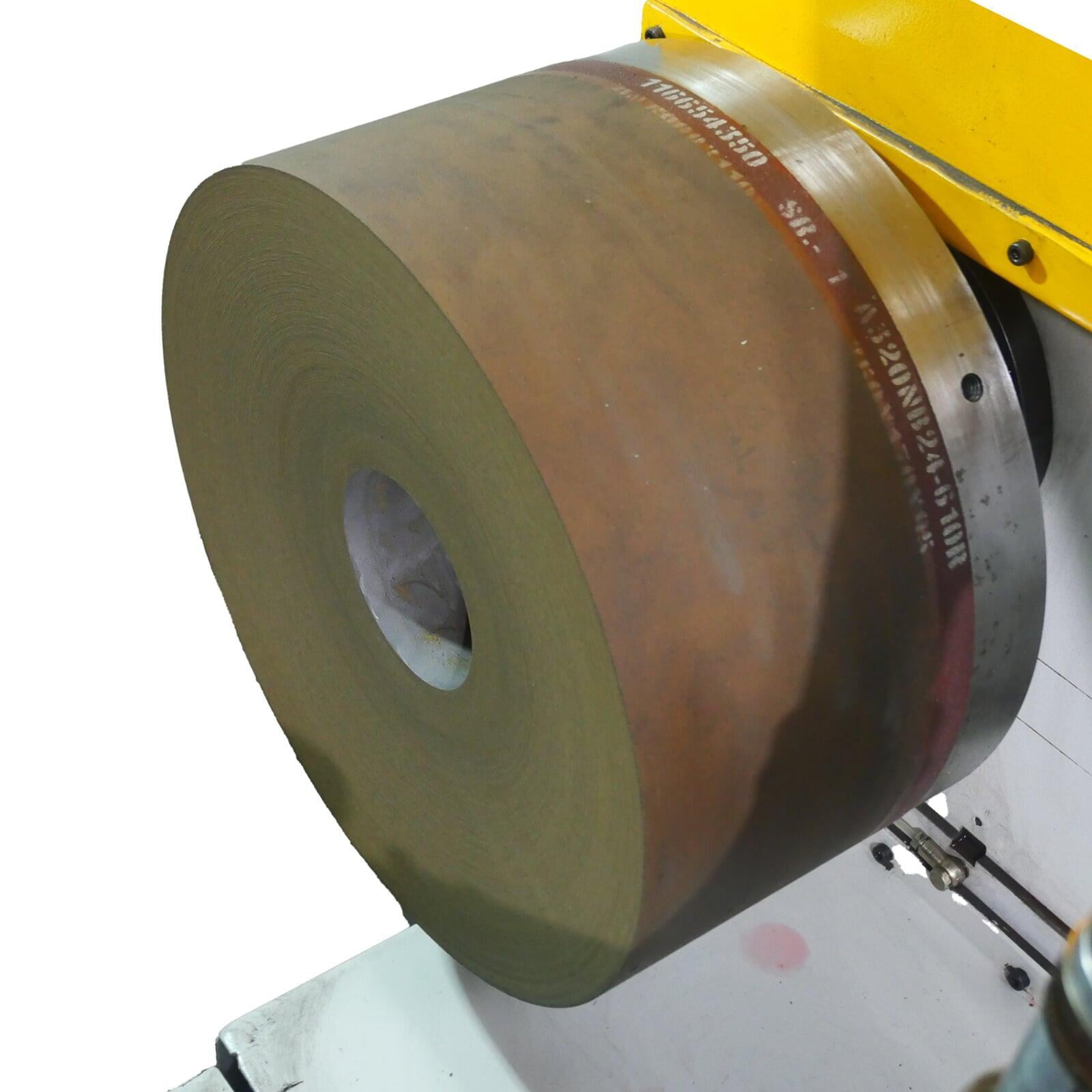

Grinding Capacity and Grinding Wheel

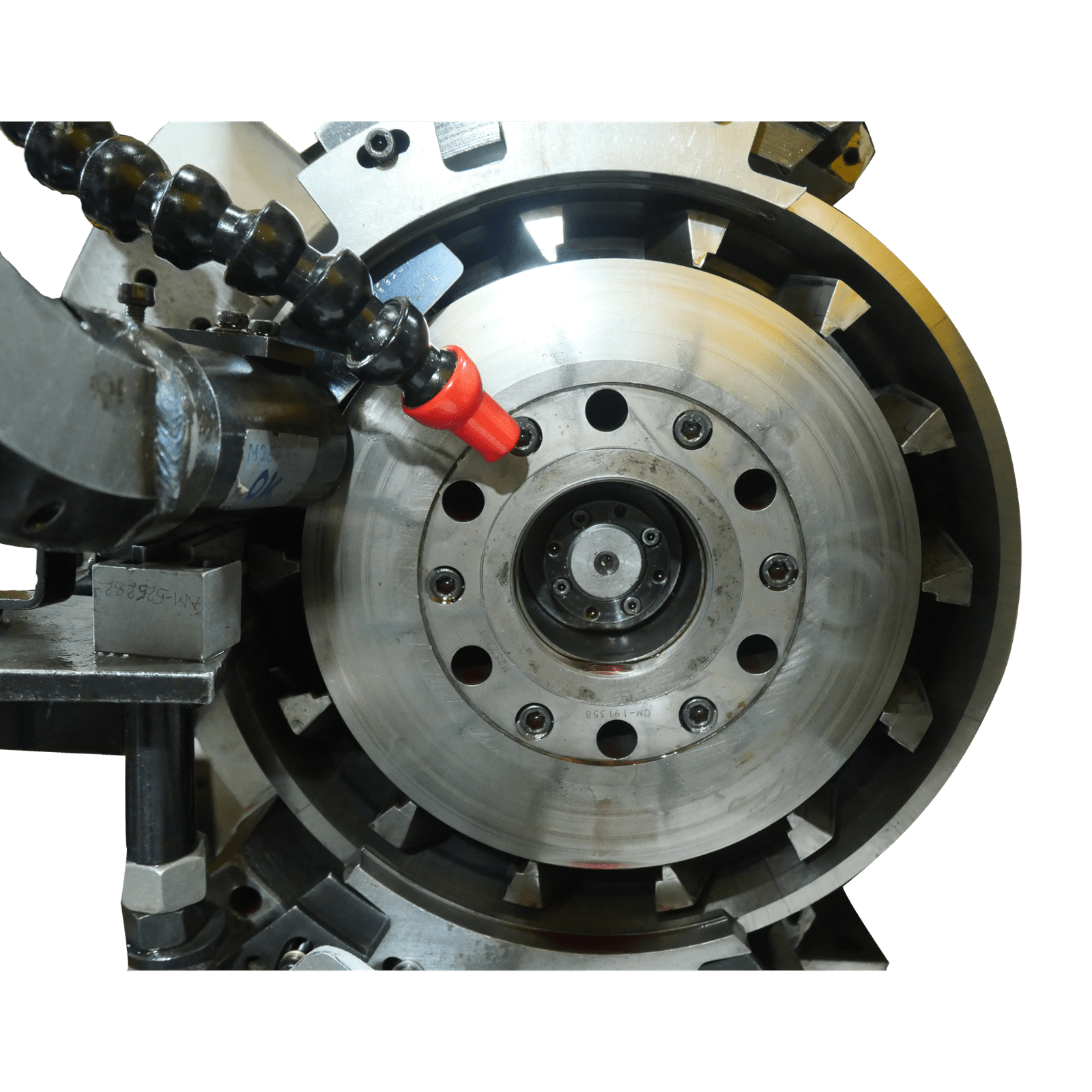

Regulating Wheel & In-Feed Slide

Grinding wheel Dresser & Regulating Wheel Dresser

CNC Control system & Power requirements

Grinding Capacity and Grinding Wheel

Regulating Wheel & In-Feed Slide

Grinding wheel Dresser & Regulating Wheel Dresser

Grinding wheel Dresser

Least Count (mm) 0.001

Servo motor (Nm) 4

Feedback system Motor Encoder

Regulating Wheel Dresser

Traverse movement-Gear motor with Ball screw and VFD

Minimum Depth of cut on diameter (mm) - 0.01

Traverse movement Feed (mm/min) -20-350

CNC Control system & Power requirements

Power requirements

Grinding Wheel Motor 15KW

Regulating Wheel Motor 3.7KW

Coolant Pump Motor 0.37KW

Lubrication Pump 0.12KW

Hydraulic Unit Motor 0.37KW

Crusher motor 1.1KW

CNC Control system

FANUC (2 axes)